We’ve got exactly what you need on this quiet Friday morning in the form of five hilarious talks from the Nicer Tuesdays archive.

from It's Nice That https://ift.tt/2X5FqDr

We’ve got exactly what you need on this quiet Friday morning in the form of five hilarious talks from the Nicer Tuesdays archive.

Our weekly round-up of jobs posted on our sister site, If You Could Jobs.

The London-based cinematographer who has worked for the likes of Nike, Adidas, WePresent and Valentino, talks us through two of her recent projects.

The Berlin-based graphic designer talks us through three recent (and very, very nice) projects.

Massachusetts Institute of Technology researchers have begun mass-producing disposable face shields for medical workers fighting Covid-19, which come flat-packed and can be folded into shape.

In a bid to meet the increasing demand for personal protective equipment (PPE) amid the coronavirus pandemic, a team of researchers at the Massachusetts Institute of Technology (MIT) have designed disposable face shields that can be rapidly mass produced.

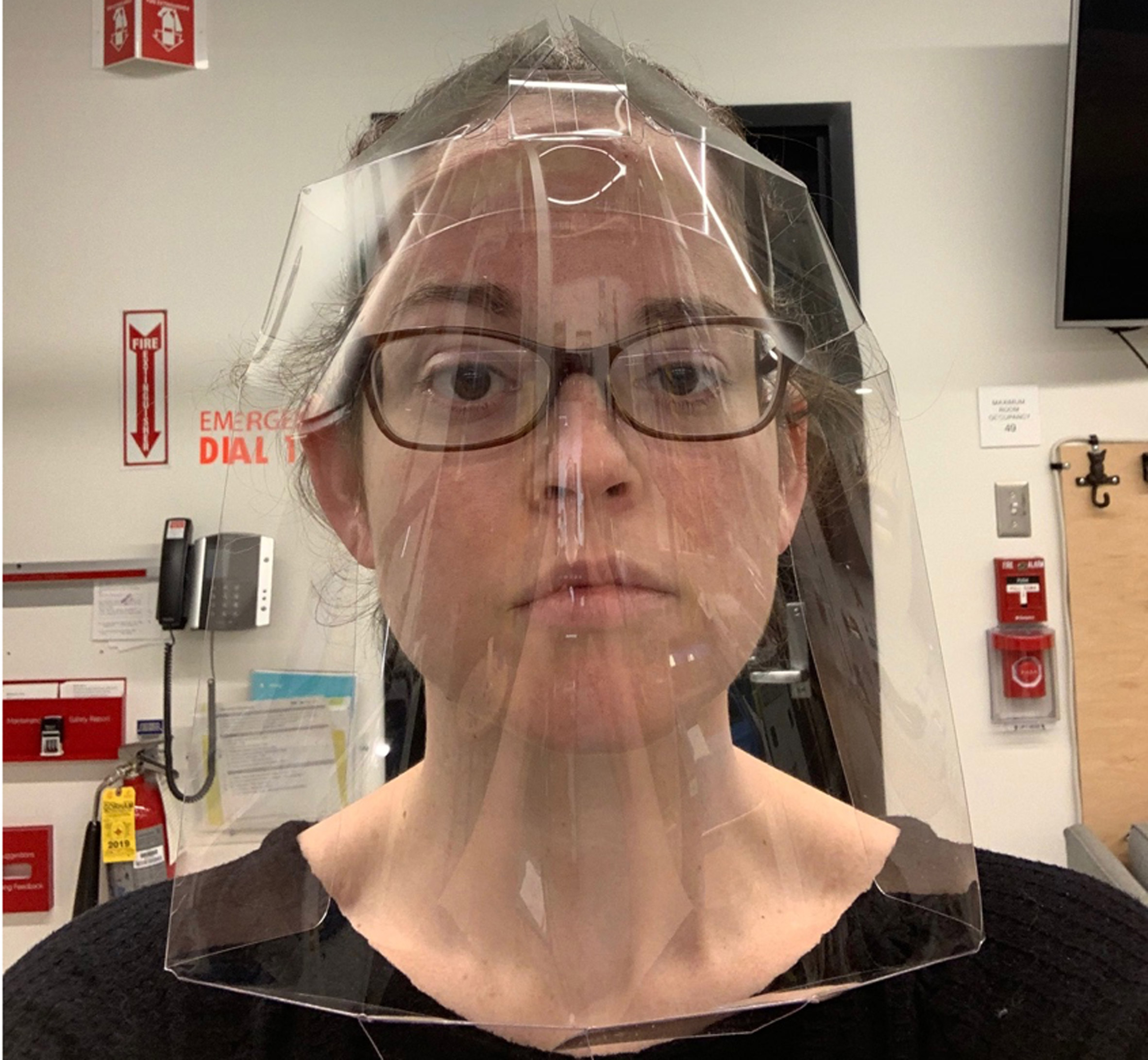

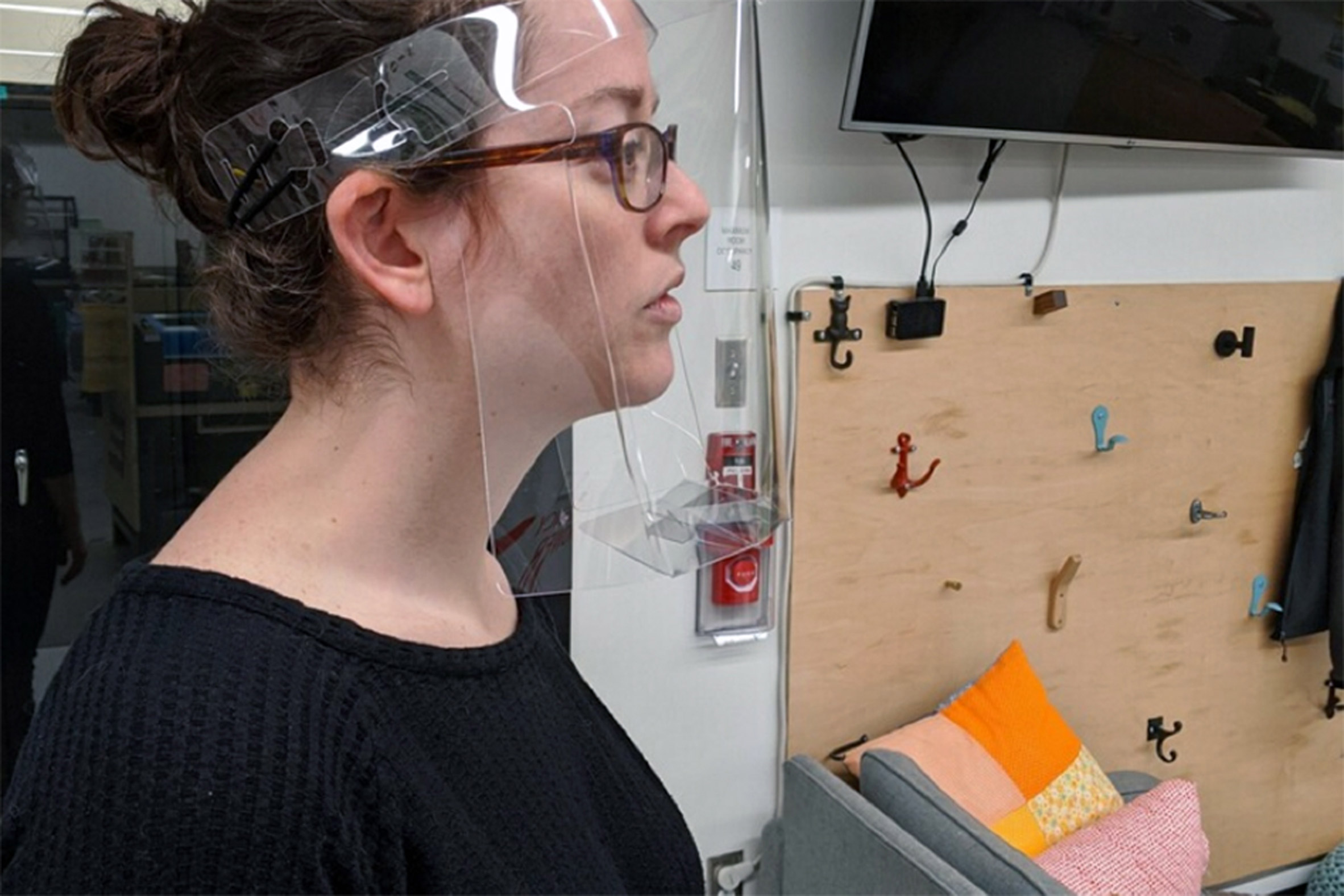

Made from a single piece of plastic, each shield comes in a flat design that can be swiftly folded into a three-dimensional structure when needed for use.

The face shields also offer additional protection with flaps that fold under the neck and over the forehead.

After testing a few materials that cracked and broke when bent, the team landed on the polycarbonate and polyethylene terephthalate glycol (PETG) materials.

"When you're thinking of materials, you have to keep supply chains in mind," said Martin Culpepper, professor of mechanical engineering and project leader.

"You can't choose a material that could evaporate from the supply chain," he added. "That is a challenging problem in this crisis."

The face shields are made from singular pieces of polycarbonate

Each single-piece shield will be made using the die-cutting process. Machines cut the design from thousands of flat sheets per hour.

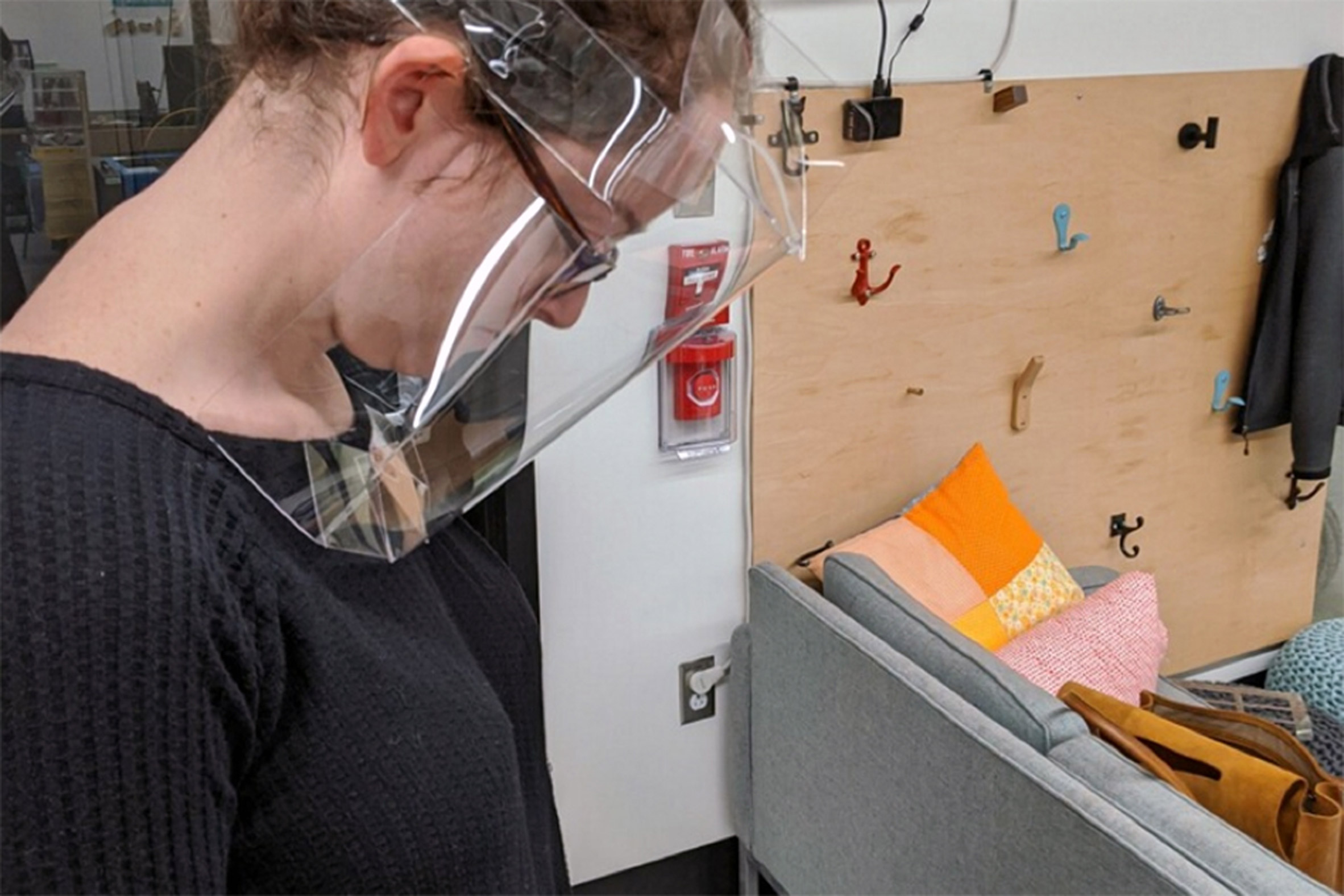

These will then be sent in their flat form to hospitals, where doctors, nurses and other frontline health care workers can quickly fold them into their three-dimensional form before adjusting them to their face.

According to MIT, the die-cutter machines used in mass production would be able to make 50,000 of the flat face shields per day.

"These face shields have to be made rapidly and at low cost because they need to be disposable," explained Culpepper.

"Our technique combines low-cost materials with a high-rate manufacturing that has the potential of meeting the need for face shields nationwide," he added.

To assemble the masks, first the protective film must be peeled away from both sides of the flat face shield.

The top strip can then be folded over to make hard creases, before folding down the visor elements to make the cover and then the side and bottom flaps.

Following this, cuts on each side of the tab coming from the top of the shield can be slotted into the two tabs positioned either side of the shield's main body.

Hair ties or rubber bands can then be attached to secure the structure into place.

MIT's plan to mass-produce the one-piece shields – labelled Project Manus – was initiated in an attempt to help fulfil the high demand for tens of millions of disposable protective equipment that will be required in the US each month.

As the team explained, when used correctly face masks should be changed every time a medical worker treats a new patient.

But due to shortages during the coronavirus pandemic, they have been asked to wear the same one all day.

"That one mask could carry virus particles – potentially contributing to the spread of Covid-19 within hospitals and endangering health care professionals," said the designers.

The clear face shields, shaped like a welder's mask, address this problem by providing another layer of protection that covers the wearer's entire face including the mask, to extend the life of PPE.

"If we can slow down the rate at which health care professionals use face masks with a disposable face shield, we can make a real difference in protecting their health and safety," explained Culpepper.

Initial fabrication of the shields was begun this week by Boston-based plastic product manufacturer Polymershapes, and the company plans to expand across the country to 55 additional locations.

"This process has been designed in such a way that there is the potential to ramp up to millions of face shields produced per day," said Culpepper. "This could very quickly become a nationwide solution for face shield shortages."

The first 100,000 shields, which are due to be made and shipped this week, will be donated to local Boston-area hospitals by Polymershapes and MIT.

Beyond these initial donations, those in need of the face shields for Covid-19-related use can fill out a request form online.

MIT is also providing the design of the face shields free of charge to verified professional die cutters, and the team has created a form for requests from companies who are interested in obtaining the fabrication files.

The post MIT develops one-piece plastic face shields for coronavirus medics appeared first on Dezeen.